The Mysterious Dust That Shapes Metal: What’s in a Blacksmith’s Magic Powder?

(What Powder Do They Put On The Metal When Forging)

Imagine a blacksmith’s workshop. The air smells like smoke. A chunk of metal glows red-hot on the anvil. Hammers clang. Sparks fly. But wait—before pounding that metal, the smith sprinkles a strange powder over it. What is that stuff? Why do they use it? Let’s dig into the gritty details.

Metal gets sticky when heated. Think of melted cheese clinging to a pan. Without help, hot metal might fuse to hammers or anvils. Worse, oxygen in the air can make it rust or weaken. That’s where the powder comes in. It’s like a superhero sidekick for metal.

Most powders used in forging are simple. One common type is graphite. You know graphite—the same stuff in pencils. It’s slippery. When heated, graphite creates a layer between the metal and tools. This stops sticking. It also keeps oxygen away, so the metal stays strong.

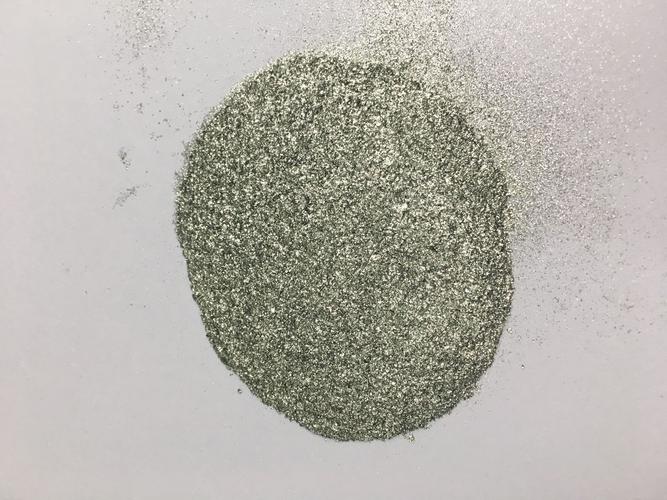

Another option is mica powder. Mica is a mineral that flakes into shiny sheets. It’s cheap and easy to find. Like graphite, it coats the metal to block oxygen. But mica isn’t as slippery. Some smiths mix it with other powders for better results.

Ever heard of borax? It’s not just for laundry. In forging, borax melts into a glass-like coating. This seals the metal, keeping air out. It’s great for welding pieces together. But borax can be messy. It leaves crusty residue on tools.

Why not use just one powder? Different jobs need different solutions. Thin sheets of metal might need graphite for smooth shaping. Thick bars might need borax for strong welds. Old-school blacksmiths often have secret recipes. Some add ash, clay, or even sand.

Powders aren’t just for manual forging. Factories use them too. Machines shape car parts or turbine blades. Without powder, metal might jam gears or scratch molds. Industrial powders are fancier. They might include ceramics or synthetic materials. But the goal’s the same: keep things moving smoothly.

Safety matters. Some powders can irritate lungs. Blacksmiths wear masks. Workshops need good airflow. Graphite is mostly safe, but borax can release fumes when hot. Knowing the risks is part of the craft.

Nowadays, even lasers and robots join the party. High-tech methods like 3D printing use metal powders. Tiny particles are melted layer by layer. These powders must be super pure. A single speck of dirt could ruin a jet engine part.

The magic powder isn’t magic at all. It’s science. It solves problems humans have faced for thousands of years. Next time you see a metal sculpture, a knife, or even a car frame, remember—somewhere along the way, a pinch of dust probably helped make it happen.

(What Powder Do They Put On The Metal When Forging)

Ancient smiths would’ve loved modern powders. But they’d likely stick to their tried-and-true mixes. After all, if it works, why change it? The clang of hammer on metal hasn’t changed much. Neither has the need for that dusty helper.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)