**Title:** The Metal Powder Puzzle: Calculating What You Need for Your 3D Printed Part

(How Many Kg Of Metal Powder To Make A 3d Part)

**1. What Exactly is Metal Powder Doing in 3D Printing?**

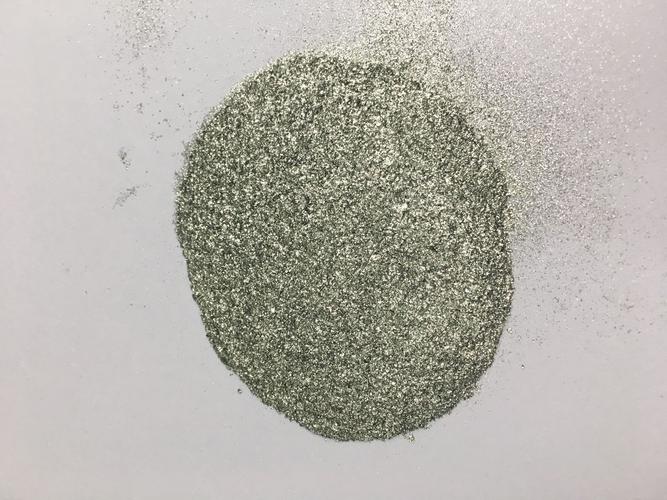

Metal powder is the essential raw material for making metal parts using 3D printing. Think of it like the flour for baking a cake. This powder isn’t just any ground-up metal. It’s specially engineered. The particles are tiny, often finer than sand. Their shape is usually spherical, like miniature ball bearings. This shape is vital. It allows the powder to flow smoothly inside the 3D printer. It also helps the particles pack together densely. During printing, a powerful laser or electron beam scans over a thin layer of this powder. The intense heat melts the metal particles precisely where the computer instructs. The melted particles fuse together solidly. The printer repeats this process. It lays down layer after layer of powder. It melts each layer selectively. Slowly, the solid metal part takes shape, embedded within a block of unused powder. This unused powder supports the part during building. After printing, workers dig the part out. They remove this loose powder. They clean the part. The metal powder transforms from a loose heap into a strong, complex metal object.

**2. Why Does the Amount of Metal Powder Matter So Much?**

Knowing how much metal powder you need isn’t just curiosity. It hits your wallet directly. High-quality metal powders, like titanium alloys or specialized steels, are expensive. Ordering too much powder ties up cash you could use elsewhere. Ordering too little halts production. You face delays waiting for more material. This impacts project deadlines. Beyond cost, powder handling requires care. Metal powders can be reactive. Some are flammable. Storing large amounts needs special containers and environments, often inert gas like argon. This prevents oxidation or dangerous reactions. Proper storage adds cost and complexity. Safety is another big reason. Fine metal dust poses inhalation risks and fire hazards. Handling less powder reduces these risks. Environmental responsibility also plays a role. While unused powder is often recycled, minimizing waste from the start is better. Efficient powder use means less energy spent recycling. It means less overall material consumption. Calculating the right amount balances cost, safety, efficiency, and practicality.

**3. How Do You Actually Calculate the Powder Needed?**

Figuring out the powder requirement isn’t as simple as weighing the final part. You need more powder than the part’s final weight. Several factors add to the total. First is the part’s solid volume. This is the actual metal in the finished, dense part. You get this from the 3D CAD model. Software calculates the volume. Multiply this volume by the metal’s density. This gives the theoretical minimum weight, the “net weight”. But you always need extra powder. This extra surrounds the part during printing. It provides crucial support. It ensures even heat distribution. It prevents warping. The amount of this support powder depends on the part’s size and shape. Complex, overhanging shapes need more support powder. The printer’s build chamber size also matters. You fill the entire chamber depth with powder, even if your part is small. The powder spreading mechanism needs a full layer. You cannot print just a tiny spot. Industry experts often use a rule of thumb. Plan for 1.5 to 2 times the net part weight. If your final part weighs 1 kg, expect to use 1.5 kg to 2 kg of powder. This accounts for the support powder and some inevitable waste during handling and recycling. Always include the weight of any necessary support structures. These are printed with the part and later removed. They consume powder too. Finally, factor in waste. Some powder gets contaminated during sieving and recycling. It cannot be reused. A 10-20% waste factor is common. So, the formula is roughly: (Net Part Weight + Support Structure Weight) x (1.5 to 2) + Waste Factor. Talk to your printer manufacturer or service provider. They know their machine’s specifics best.

**4. Real-World Applications: From Tiny Gears to Massive Frames**

The amount of metal powder needed varies wildly. It depends entirely on the part being made. Small, intricate components, like dental implants or tiny aerospace sensors, might only need a few grams or tens of grams of powder. Even so, the printer chamber requires a minimum powder load, often several kilograms. You might use only a fraction for the part itself. The rest supports it. Medium-sized parts are common. Think automotive components, custom surgical tools, or robust drone parts. These might weigh a few hundred grams to a couple of kilograms finished. Powder usage could range from 1 kg to 5 kg or more. Large industrial parts push the limits. Examples include structural brackets for aircraft, sections of rocket engines, or big hydraulic components. These finished parts can weigh tens or even hundreds of kilograms. Powder requirements soar accordingly. Easily reaching 50 kg, 100 kg, or much more. The material choice also impacts the weight. Aluminum powder is lighter than stainless steel powder. Stainless steel is lighter than tungsten or Inconel powders. A large aluminum part might need less powder by weight than a smaller stainless steel part. The application drives the size. The size and material drive the powder need.

**5. FAQs: Your Metal Powder Questions Answered**

**Q1: Can I just weigh the final part and know how much powder I used?** No. The final part weight is only part of the story. Significant powder remains unused as support material surrounding the part during printing. This support powder is reclaimed. Powder is also lost to waste during handling and recycling. The powder used is always more than the final part weight.

**Q2: Is all the unused powder wasted?** Absolutely not. Most unused powder surrounding the part is carefully recovered. It goes through sieving to remove lumps or debris. Often it gets blended with fresh, virgin powder. This mixture is reused for future prints. This recycling is crucial for cost control. However, some powder is inevitably lost or contaminated beyond reuse. This is the waste factor.

**Q3: Does the type of 3D printing machine affect powder usage?** Yes, slightly. Different metal 3D printing technologies exist. The most common are Powder Bed Fusion (like DMLS/SLM) and Binder Jetting. Powder Bed Fusion typically has higher powder usage factors. This is because the entire build volume is filled with powder. Only the part area is melted. Binder Jetting might allow slightly tighter packing. The core principle remains similar. Support powder and waste still apply.

**Q4: How does part complexity change the powder needed?** Very complex parts with lots of overhangs or internal channels need more support structures. These supports are printed from the same powder. They add directly to the powder consumed beyond the final part’s net weight. Complex parts might push you towards the higher end of the powder multiplier (closer to 2x).

(How Many Kg Of Metal Powder To Make A 3d Part)

**Q5: Why is density important in the calculation?** Density tells you how heavy a certain volume of the solid metal is. Powder particles have air gaps between them. The printed part, after melting, is solid. To find the net weight of the final solid part, you need its volume (from CAD) multiplied by the density of the solid metal alloy. Different alloys (stainless steel, titanium, aluminum) have different densities. This directly impacts the weight.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)