Rescuing Your Powder Coated Metal From Rust Invasion!

(How To Repair Rusting Powder Coated Metal)

Powder coated metal looks tough. It feels tough. But sometimes, you see it. That dreaded orange-brown enemy creeping out from a scratch or chip. Rust. Seeing it on your powder coated patio set, bike frame, or garden gate feels like a betrayal. Don’t panic. Rust on powder coated metal isn’t always a death sentence. You can fight back. Let’s learn how to rescue your metal and restore its good looks.

**1. What Powder Coated Metal Really Is**

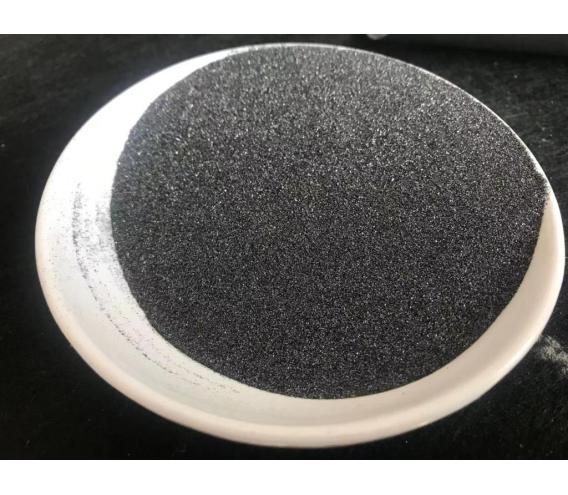

Think of powder coating as armor for metal. It’s not like regular paint you spray wet. Instead, it starts as a super-fine, dry powder. This powder gets sprayed onto the clean metal surface. The magic happens next. The coated metal piece goes into a big oven. The heat melts the powder. It flows smoothly over the metal. Then, it cools down hard. The result is a thick, durable, smooth finish. This finish sticks to the metal incredibly well. It’s much tougher than standard paint. It resists chipping, scratching, and fading from sunlight much better. You see it everywhere: outdoor furniture, car parts, fences, appliances, and building facades. It’s popular because it lasts a long time and looks great. But even armor can get chinked.

**2. Why Powder Coated Metal Rusts Anyway**

So, if it’s such tough armor, why does rust appear? The answer is simple. The armor got breached. Powder coating shields the metal perfectly. But it’s only perfect if the coating stays whole. Any damage breaks the shield. A deep scratch from moving furniture. A chip from a flying stone. A ding from a dropped tool. Even a tiny flaw matters. Once the bare metal underneath is exposed, it’s vulnerable. Air and water reach the metal. This starts the rusting process. It begins right at the damage point. Worse, rust can creep sideways. It sneaks under the surrounding good coating. This lifts the coating away from the metal. This makes the damaged area bigger. Environmental factors speed this up. Salt near the ocean is brutal. Road salt in winter is harsh. Constant dampness or high humidity helps rust grow faster. Neglect makes it spread. Ignoring a small chip lets rust take hold and expand.

**3. How to Fix Rust on Powder Coated Metal**

Catching rust early is key. Small spots are fixable. Big areas might need professional help. Here’s your battle plan:

* **Gather Supplies:** You need safety glasses, gloves, a dust mask (for sanding), coarse sandpaper (80-120 grit), fine sandpaper (220-320 grit), rubbing alcohol or wax/grease remover, clean rags, rust converter liquid (optional, for bad spots), metal primer (etching primer is best), matching touch-up paint (spray can or brush-on), clear coat (optional, for gloss), small paintbrushes, masking tape, and newspaper or drop cloths.

* **Prep the Area:** Cover surrounding areas well with newspaper and tape. Protect anything you don’t want paint or rust dust on. Work outside or in a very well-ventilated space.

* **Attack the Rust:** Put on your safety gear. Sand the rusty area aggressively with coarse sandpaper. You must remove every speck of rust. Scrape it off. Dig it out. Rust must be gone. Sand beyond the visible rust too. Go into the surrounding good coating a little bit. This ensures you remove rust hiding underneath. Feather the edges of the good coating smoothly. Switch to fine sandpaper. Smooth everything out. Wipe away all dust with a tack cloth or damp rag. Let it dry completely. Clean the bare metal spot thoroughly with rubbing alcohol. Remove any grease or oil. Let it dry again.

* **Treat Stubborn Rust (Optional):** For deep pits or spots you worry about, apply rust converter. Follow the product instructions exactly. It turns rust into a stable, paintable surface. Let it dry fully.

* **Prime the Metal:** Bare metal needs primer. Spray a light coat of etching primer directly onto the cleaned, sanded metal spot. Hold the can the recommended distance. Primer helps the topcoat stick and prevents future rust. Let the primer dry completely. Check the can for drying time. Lightly sand the primed area with fine sandpaper once dry. Wipe away dust.

* **Apply the Color:** Now for the color coat. Shake your touch-up paint well. Apply thin coats. Don’t try to cover it all in one go. Better to do 2-3 thin layers. Let each coat dry completely before adding the next. Thin coats prevent runs and sagging. Match the original color as closely as possible.

* **Seal and Protect (Optional):** If your original finish was glossy, consider a clear topcoat. Apply it over the dried color coat. Use thin layers again. This adds extra protection and sheen. Let everything cure fully according to the paint instructions before using the item.

**4. Where Powder Coated Metal Shines**

Powder coating isn’t just for looks. Its toughness makes it perfect for many demanding jobs. Think about things that live outside. Patio furniture faces sun, rain, and wind. Powder coating protects it. Fences and railings battle the elements constantly. Powder coating keeps them looking good longer. Car parts like wheels, bumpers, and trim need to resist road salt, gravel, and grime. Powder coating handles it. Garden tools and machinery benefit from this durable shield. Inside homes and offices, you find it too. Appliance panels, light fixtures, shelving units, and filing cabinets often wear powder coats. Industrial settings rely on it. Factory equipment, electrical enclosures, and structural parts use powder coating for long-lasting corrosion resistance. Its ability to cover complex shapes evenly makes it versatile. It comes in almost any color and texture. This durability and flexibility explain its huge popularity.

**5. Powder Coated Metal Rust Repair FAQs**

* **Can all rusted powder coating be fixed?** Small spots where rust hasn’t spread far under the coating are fixable. Large areas, widespread bubbling under the coating, or deep structural rust mean the piece might need stripping and recoating professionally. Or it might be beyond saving.

* **How long does powder coating last before rusting?** Properly applied on well-prepared metal, powder coating lasts 15-20 years or more. Exposure to harsh conditions (salt, chemicals, constant abrasion) shortens this lifespan. Damage is the main cause of early rust.

* **Is it worth fixing, or should I just replace it?** Fixing small rust spots is cost-effective and extends the life of your item. For expensive items like patio sets or bike frames, repair makes sense. For cheap items with major rust, replacement might be cheaper.

* **Can I prevent rust on powder coated metal?** Yes! Inspect items regularly, especially after winter or storms. Look for chips or scratches. Clean items gently with mild soap and water. Avoid harsh abrasives. Dry them well. Apply automotive wax to outdoor items once or twice a year. This adds a protective layer. Fix any damage immediately before rust starts.

(How To Repair Rusting Powder Coated Metal)

* **Will my touch-up paint match perfectly?** Getting an exact match can be tricky. Sunlight fades colors over time. Try to get paint from the original manufacturer. Test the color on a hidden spot first. Even a close match looks better than rust, and protects the metal.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)